Machine : 3D Printer

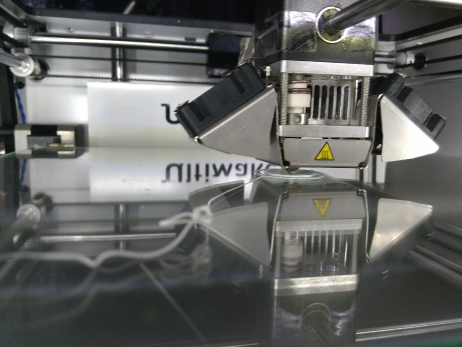

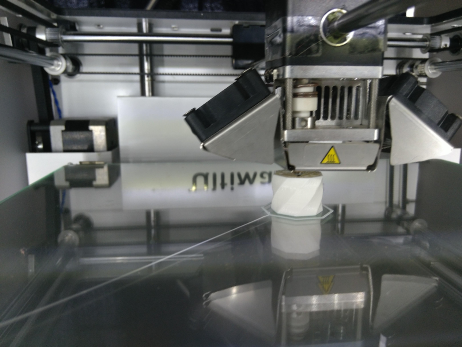

In the begining

In the begining

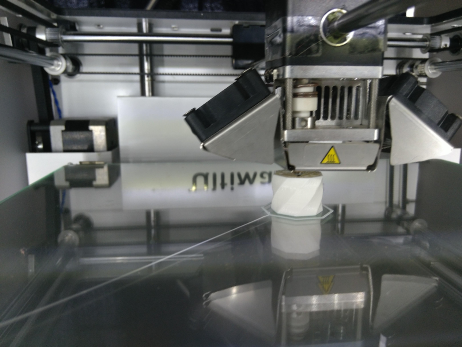

Midway

Midway

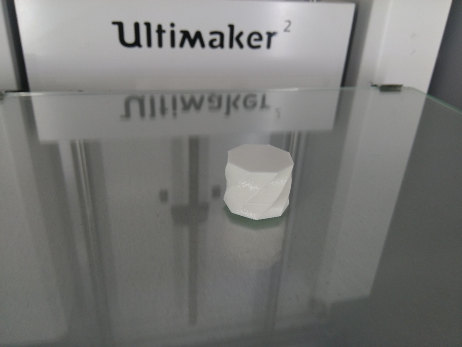

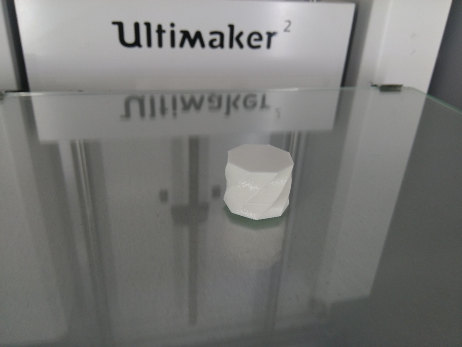

Finished model

Finished model

We started with Antimony software. Made a 3D design file for keeping the bits of the modella.

Afternoon session was on 3-D printing.

Design: Take care of the levelling of the plate and make the distance between extruder head and the plate optimum. 45 degree is the maximum allowable slope. If it is higher than 45, the software will add support material. We must try to avoid the use of the support material. Positioning of the shape is also very crucial. The orientation will change according to the application of the printed object.

Controllable parameters:

- speed : slower the better, normal speed 50mm/sec

- temperature : lower the better, find the minimum temp and use that.

- fill density : lower density saves material but lowers the structural robustness.

- speed in between printing layers. We can make it wait in between layers for the plastic to solidify.

- thickness of the layer : 100 micron is standard. 60 is great, anything below, don't bother. 150 if you are in a hurry.

In the begining

In the begining Midway

Midway Finished model

Finished model